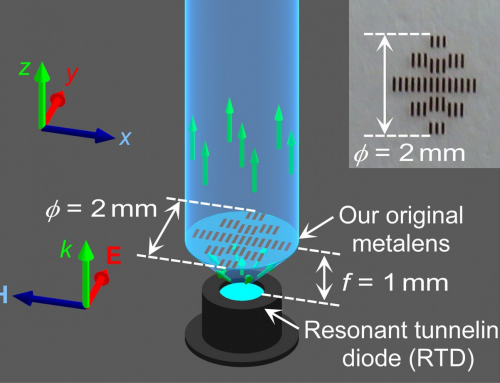

Terahertz radiation (range between microwaves and far infrared) penetrates the air and materials, which do not contain water, such as plastic, wood, cement, paper, fabrics and many others. As it passes through successive layers, part of the waves is reflected from their surfaces, creating a sequence of pulses separated by time difference, which can be used for precise and non-invasive calculations of the thickness of the tested coats (more about mechanism on the example of TBC topcoats measurements). Therefore terahertz radiation are already used in the automotive industry – to test the thickness of paints, or in the aviation – to estimate the wear of coatings that protect aircraft turbines from heating up.

Interestingly, the unique feature of the radiation in 0,1 – 2 THz frequency range is that there is a high disparity between liquid water absorption and ice absorption. Ice is 100 times more permeable to the radiation than liquid water*. This creates the possibility of using terahertz waves also In food industry.

Scientists from the Technical University of Denmark (DUT) in cooperation with a fishing company – Royal Greenland, are working on a technology, which uses this range of radiation to measure the thickness of the glaze (thin ice layer) on frozen food.

Niels Bøknæ, process developer at Royal Greenland explains why an even layer of ice on the frozen prawns is so important:

“The glazing protects the prawns from unwanted chemical changes. As long as the prawns are frozen, it’s not so much about food safety, but more about quality. The ice glazing prolongs the shelf life, because—without it—the prawns would dry out and not taste very good. We glaze by spraying water from nozzles on the deep-frozen prawns. The glazing is done with differences in process parameters. Maybe the water from the water nozzles is slightly too hot or cold, and the size of the prawns may vary a little. This means that the glazing thickness is not completely constant, and it’s really a challenge to control the glazing content in the practical production.”

Such a products are usually sold by weight, disregarding the weight of ice. Therefore, when customer buys 200 g of frozen seafood, he should receive at least 200 g of the defrosted products. In order to minimize unfavorable deviations from desired weight – for the client or the producer and to ensure good quality of food, the glazing process should be monitored. Currently checks are carried out selectively, without automatically adjusting the thickness of the ice to the size of the products.

Scientists in the GLAZE research project are trying to refine the method of measuring thickness using terahertz radiation and reduce the costs of whole system.

“We started with a system that cost 1.5 million Danish kroner. If we’re to use the technology in the food industry, the price of our terahertz system must come down a lot. So we looked at whether we could produce a more inexpensive version by replacing the most expensive components with cheaper versions based on well-known semiconductor technology” says Simon Lehnskov Lange – postdoc at Department of Photonics Engineering (DTU Fotonik).

The researchers receive help from FORCE Technology, where the role of the Centre for Applied Photonics includes ensuring commercialization of Danish, photonics-based technology.

A prototype model, ready for testing, that could be put into mass production in the future, is likely to appear by the end of 2021.

Reference: Remote Infrared Radiation: New Technology Measures Thickness of Ice on Prawns, Eric Bendix